This MU Project training period took place from Spring to Summer in 2006.

The progess was fine and we finished the product at the end of June. Here is a general review of the workflow.

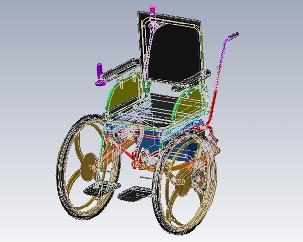

Saturday Period_ Eletric Foldable Wheelchair Design

The original topic of our topic was Electric Foldable Wheelchair. During the Saturday period, we did the research and design of the wheelchair.Before the period ended, we had the design finished.

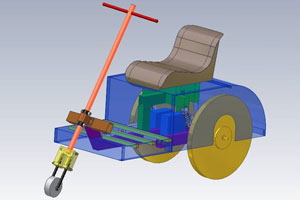

Week 1 - Week 2_ Electric Tricycle Design

After the examination we were informed that our topic had been changed. Electric Tricycle was the new topic and redesign had to be done.We spent one and a half week to design and confirm the overall structure, dimension and material used before the manufacturing could get started.

Week 2_ Diagram Sheets and Material Selection

It was necessary to produce the diagram sheets and decide the materials being used. Around 2 days were spent to do the job and diagram sheets were printed out before we started the work. All materials were ordered as well.

Week 3 - Week 4_ Frame Manufacturing

We started to work on the frame of the tricycle first. The processes involved were mainly machining and welding. Here we divided our group to work on different workshops simultaneously. Bushes, rings and shafts were produced in the machining workshop. Frame body of the tricycle was finsihed in the welding workshop.

Week 4_ Initial Assembly

After the frame and small parts were finished, we did an initial assembly before working on the body cover. Generally the tricycle could run smoothly without any problems. Some parts were adjusted for their dimensions to make the tricycle more comfortable for users.

Week 4 - Week 5_ Body Cover

Sheetmetal was used to make the body cover of the tricycle. After the desired shapes were cut out and folded, we assured that the body cover could fit the frame.On the second last day of the training period, we did a little decoration work on the body cover. Patterns were drawn on the cover and spray painted.

Week 5_ Final Assembly

On the last day we carried out the final assembly. With the successful initial assembly and assured fit between the frame and the body cover, the final assembly did not give us a hard time. Getting the body cover fixed on the frame, we finished our product assembly with no obstacles.